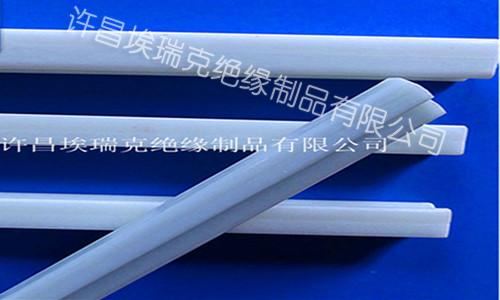

Insulation support rod manufacturer

Product features and usage:

Fiberglass brace, also known as I-shaped bar, pull-out bar, ventilation bar, etc., is a type of profile produced by extrusion process using alkali free glass fiber impregnated thermosetting resin. It has advantages such as high mechanical strength, excellent electrical performance, flame retardancy, corrosion resistance, and arc resistance. According to different raw materials and processes, F-grade and H-grade support bars can be produced, mainly used for interlayer ventilation and cooling of dry transformers, as well as for use on reactors and wave arresters.

I-bar specifications:

six × 6 8 × 20 10 × 16 13 × 19 15 × 15 20 × one hundred and eighty-four × eight

eight × 10 10 × 15 13 × 16 14 × 24 18 × twenty

six × 8 10 × 8 10 × 19 14 × 12 16 × sixteen

six × 9 10 × 10 12 × 12 14 × 16 16 × 18

eight × 8 10 × 12 12 × 14 14 × 18 16 × twenty

eight × 9 10 × 13 12 × 16 14 × 20 16 × twenty-two

Product advantages:

1. The extruded fiberglass support rod product can be used in high-voltage electrical equipment (such as high-voltage switches, transformers, capacitors as insulation structural components, communication equipment as insulation components for antennas, stringing pillars, and money line conductors, engineering pull rods for coal mines and mine tunnels, suspension rods on grain machines, oil field pull rods, non-metallic fiber optic cable support rods, organic composite insulator core rods, and other places).

2. The pultrusion products have the following characteristics

High mechanical strength: Due to the use of unidirectional fibers with a content of up to 70% as reinforcing materials, pultruded products have high tensile, tensile, and compressive strength.

3. Lightweight and cost-effective to use

The proportion of extruded products is about 4 times lighter than steel and 30% lighter than aluminum, making it easy to transport, install, and maintain. Its comprehensive economic benefits are good.

4. Excellent electrical insulation

Due to the small air gap of the extruded products, their electrical insulation performance is excellent.

5. Accurate and stable size

The coefficient of thermal expansion of pultrusion products is lower than that of most plastics and steel, and it is not hygroscopic, so the dimensions are stable.

6. Chemical resistance

The pultruded product body is made of inorganic fibers, and the adhesive used - unsaturated polyester or epoxy resin - has excellent chemical corrosion resistance. Therefore, the pultruded product is also an excellent chemical corrosion resistant substance.

7. Good application craftsmanship, wide application range, customers can freely design cross-sectional dimensions.

Extruded products can be formed in one go according to user requirements. Products with different cross-sectional shapes and length requirements have accurate dimensions, small tolerances, good surface finish, no need for mechanical processing, and can be directly applied, which is very convenient.